Okay FB2512 Flanging Machine is specially designed for the flanging of the airduct pieces for fan

industries. Especially for the auto flanging, punching and forming for the stiffed edges for the

barrels, airducts, pipes for the fan industies. The machine can flange any angle and arc no more

than 90º.The machine is centralized controlled by Siemens 828D high-end CNC system.

It can not only be easily operated and with high efficiency, but also the manufactured parts with

high standard level and universalization.The machine designed with novel ideas; can run smoothly

and high automation.

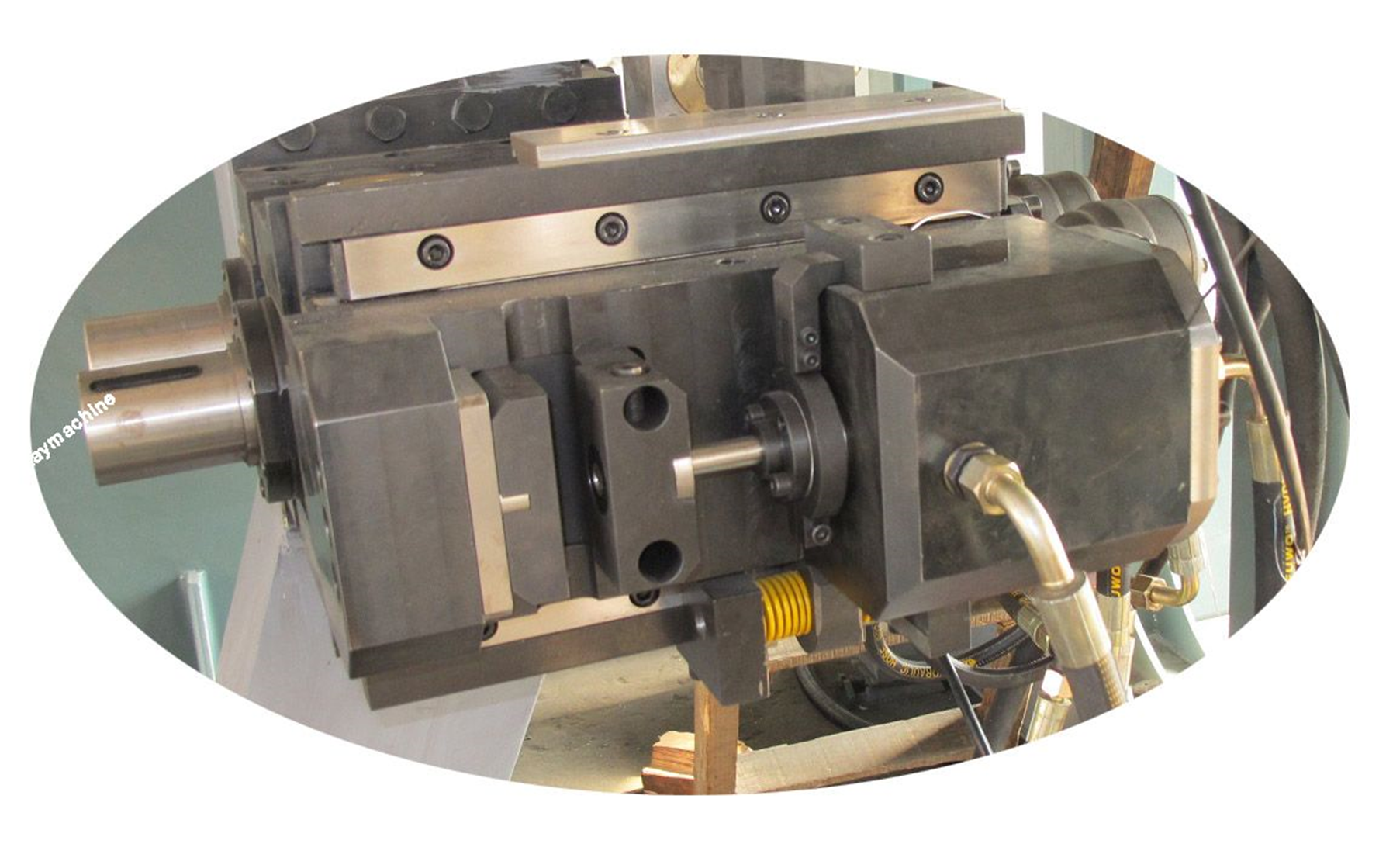

The flanging is fulfilled by cnc system insert step movement. The programing is edited by our own

develped software. It is convinient and reliable. The punching is driven by hydaulic cylinder. The

pitch dividing is controlled by servo motor.

The machine are widely used in forming of the pipe conecting flange in the fields, like fan and blower, petroleum, chemical industries, and powder transportation, etc.

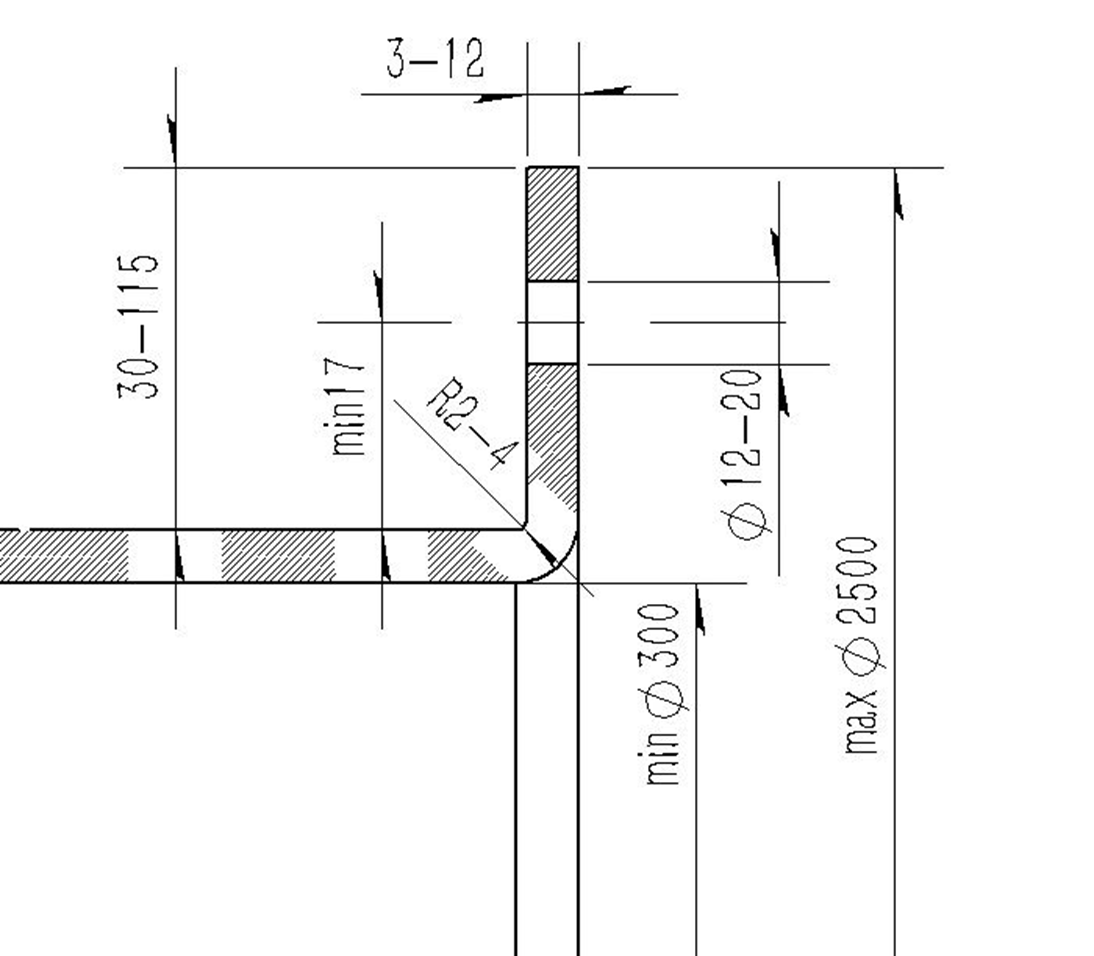

Max Airduct Diameter 2200mm

Max Flange diameter 2500mm

Min Airduct Diameter 500mm

Max Length 1500mm

Min length 200mm

Max thickness (Carbon steel) 12mm

Max Hole Diameter 24mm

The Mold Expander stroke 30mm

The Mold Expander Force 2000KG

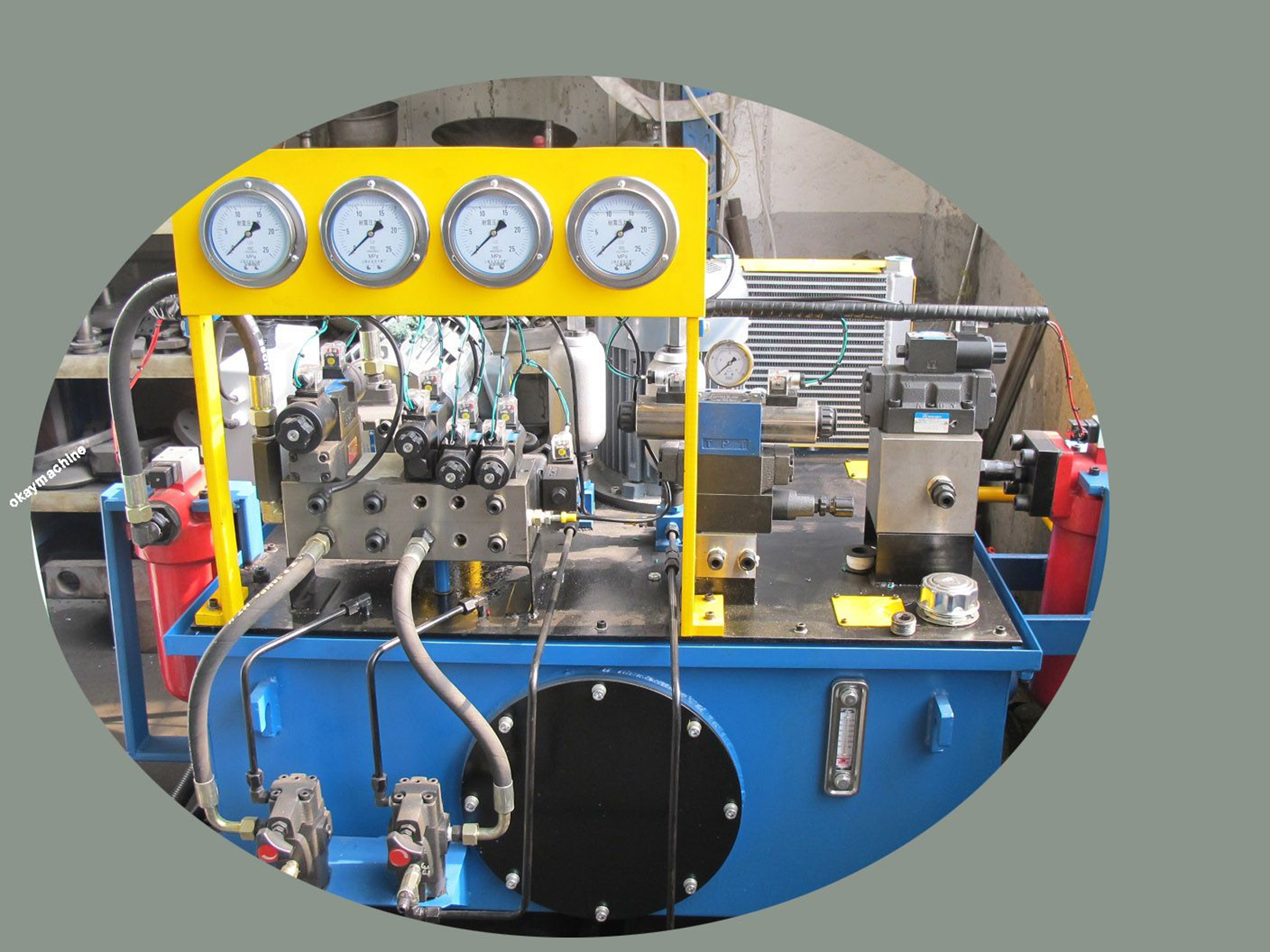

Hydraulic Station Power 22KW

Assistant Drive Power (Hydraulic Motor) 150NM

Spinning Wheel driving Motor Siemens 1FK7 Servo Motor

Driving System Siemens S120 Series

Control system Siemens 828D CNC system

Punching Power Hydraulic

Spindle Speed 50-300 rpm

Hydraulic Tank Capacity 320L

Cooling System for Hydraulic Oil Atuomatic control

Diemension 6100 (L)*3700 (W)*2800 (H)

Power Consumption 55KW

Weight 23000kg

Machine for fan

Copyright © 2024 Shanghai Okay Machine Co., Ltd ICP: